The tapered roller bearing is a separate type bearing. Both the inner ring and the outer ring of the bearing have a tapered raceway. The inner ring and a group of tapered rollers are enveloped by a basket-shaped cage. The outer ring can be separated from the inner ring assembly. The tapered roller bearing is 100% interchangeable between the outer ring and the inner assembly. The bearing is designed to adapt to the combined load, that is, the radial and axial loads acting at the same time. The extension line of the raceway converges at the same point on the bearing axis to achieve real rolling, so it has a low friction torque during operation. The axial load capacity of tapered roller bearings increases with the increase of contact angle, and the magnitude of contact angle is related to the calculation coefficient. The larger the value, the larger the contact angle.

Single-row tapered roller bearings can bear radial load and single-direction axial load. The axial load capacity depends on the contact angle, that is, the outer ring raceway angle. The larger the angle, the greater the axial load capacity. When the bearing bears the radial load, it will produce an axial component force, so when another bearing which can bear the opposite axial force is needed to balance, compared with the angular contact ball bearing, the bearing capacity increases and the limit speed decreases.

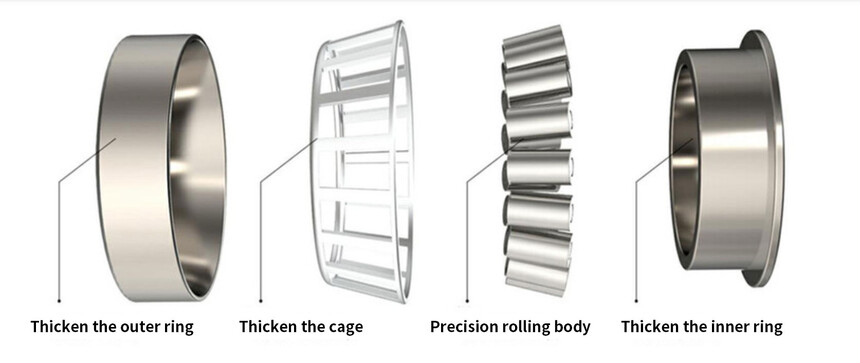

Cage material

Tapered roller bearings generally use steel plate stamping basket cage, but when the size is larger, the vehicle solid pillar cage is also used.

Allowable tilt angle

The tapered roller bearing shaft is tilted relative to the housing hole, and if there is an inclination, it shall not exceed 2'.

Tolerances and clearance

Tapered roller bearings generally have a tolerance of class 0, and bearings with higher tolerances can be manufactured as needed. The clearance of single-row tapered roller bearings can be adjusted by users according to different requirements, and the radial clearance of double-row and four-row tapered roller bearings can be provided according to the following table according to user requirements. In the course of use, when the user needs to change the clearance, it can be adjusted according to the relevant regulations.

Main use

Automobile front wheel, rear wheel, transmission, differential, household appliances, traffic vehicles, machine tool spindle, construction machinery, large agricultural machinery, railway vehicle gear deceleration device, rolling mill roller neck small deceleration device and so on.

Characteristics and advantages

Low friction, noise and vibration.

Long service life.

Operation reliability can be increased even under difficult conditions.

The running-in stage of peak temperature drop.

Detachable and interchangeable parts are easy to install, disassemble and maintain